PEZY GROUP

PAPER PACKAGING

3 years - Medior Product Developer

I contribute to the design, engineering and manufacturing support of healthcare products, sustainable packaging’s and innovative consumer products (e.g. epilators, deodorants and vacuum cleaners).

The nature of my work at Pezy Group is confidential. Therefore, I am not able to show detailed project visuals and explain project specifics. However, I provide a brief description of the work I enjoy doing at Pezy Group below.

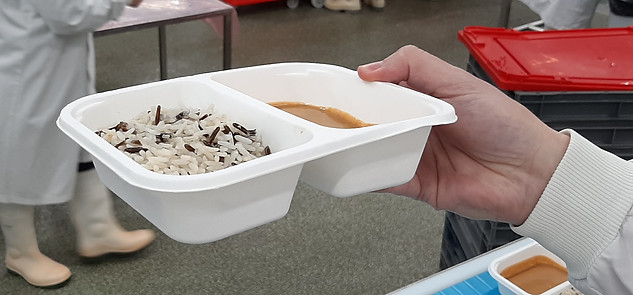

As an interim professional, I strengthened the innovation projects at a global specialist in paper food packaging. This client produces paper packaging by the wet-pressing process technique. The aim is to replace single used packaging with paper packaging. For over a year, I helped with the development and implementation of several packaging.

I enjoyed working for this client a lot. During the projects, I gained large experience in this paper production process. In addition, this period gave me skills in cooperating in an international work environment with different disciplines. Examples of my responsibilities are:

-

Visiting manufacturing and logistic sites in the Netherlands and the UK. Analysing production and logistic process and creating a Root cause analysis. Create implementation suggestions to optimize the production process and logistic process. Presenting and discussing my analyse with production and marketing managers and decide on action points.

-

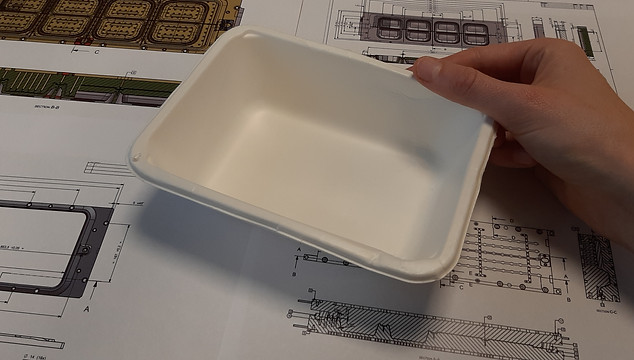

Responsible for the engineering of new paper packaging trays and also the engineering of the production moulds. In this project phase, I had close contact with the supplier of these moulds. I was responsible for the planning and the purchase of the new moulds.

-

Managing the validation process. Setting the Critical to Quality lists and setting first production trials. For example, using a compression testing machine to perform research on the strength of products. Analysing and summarising test data, writing the technical reports and presenting the findings to the interdisciplinary teams.

Testing the paper tray on the fool fill line.

Designing the trays and engineering the test and production moulds.

Engineering of the mould and testing the first production trials.

Analyse the quality of sustainable paper food trays.

CIRCULAIR PRODUCT

DEVELOPTMENT

I contributed to the engineering of a new wireless sensor case. The client is an expert in the field of radio antenna technology and measurement data processing. This product is including various sensors. The product can be used in industries like factories, growers, tech companies and laboratories.

During this project, I learned a lot about circular product development. The design contains Design For Recycling principles. The product is made from post-consumer recycled plastic. The product also contains Design From Recycling principles. After use, it will be possible for the waste processors to process the plastic product into new raw material for new quality products.

Besides the circular product development principles, I increased my knowledge of plastic product development.

-

Engineering the components and assemblies in 3D CAD. Developing mechanical functions like strengthening construction, reducing weight and improving the model for the injection moulding process. Discussing the details with lead product engineers and deciding together the follow-up action points.

-

Presenting and discussing the 3D model updates with clients and moulding engineers.

-

Responsible for creating realistic concept renders in Keyshot.

-

Optimising the CAD file for plastic injection moulding, for example, checking drafts, wall thickness, the strength of the construction and adding measure surfaces.

-

Setting up technical 2D drawings and review with mould engineers.

-

Performing tolerance analyses and discussing improvements within the project team.

-

For the first time, seeing a product I have been working on coming out of the injection-moulding machine in our in-house pilot factory!

Model 3D CAD files for a smart sensor case designed from and for recycling.

Produced from recycled plastics and designed for the recycling process.

Prepare the 3D CAD file ready for production plastic injection moulding.

Render of the exploded view and the waterproof feature of a multi-sensor .

Investigate the tolerance chain.

CONSUMER GOODS

Generating, developing and visualizing creative conceptual ideas for consumer good products. For example, new-to-the-world deodorant principles, eclectic female epilators and packaging's for child nutrition.

These projects gave me various experiences in the first phases of product development. I worked closely together with the market and design departments of our clients. Therefore, I also gained experience in presenting project status, keeping project planning and aligning next steps with the clients.

-

Performing analysis to give the first insights into the functions, uses, brand, competitors and production technique.

-

Write a project proposal, including a problem definition, project planning, setting project challenges, defining deliverables and budget outlines.

-

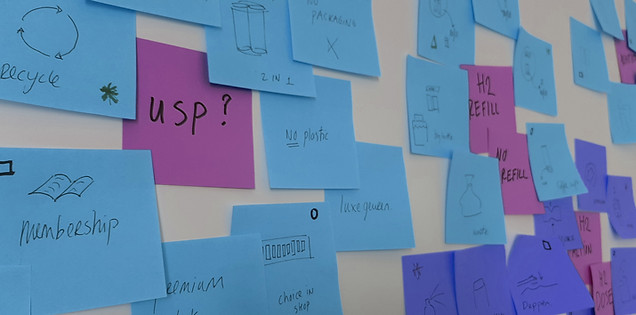

Exploring the market proposition and selecting the Unique Selling Points.

-

Facilitating creative brainstorming sessions. In these sessions, I lead a team through a creative process to generate a new vision, new opportunities for the organizations or solve technical problems. After the brainstorm, I screen the ideas, clarify open points and define integral concepts.

-

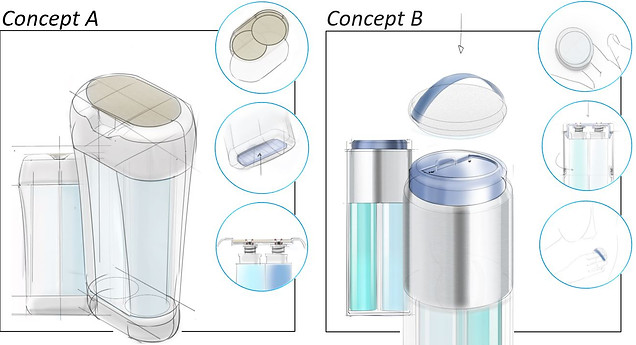

Visualising the product ideas into strong conceptual paper drawings or digital drawings (Photoshop)

-

Make a rough CAD model to get the first impression about functions, part sizes, weight and design. Responsible for creating realistic concept renders in Keyshot.

-

Build quick mock-ups with 3D prints, paper, foam, clay or fabric and perform quick user and functional tests.

-

Presenting the concepts to the clients and deciding together with the client the follow up of the projects.

Fascilitate a meeting to explore Unique Selling Points for an innovative deoderant.

Idea sketches during a brainstorm session for a more light-weighted deodorant.

Digital concept drawings of an innovative deodorant idea.

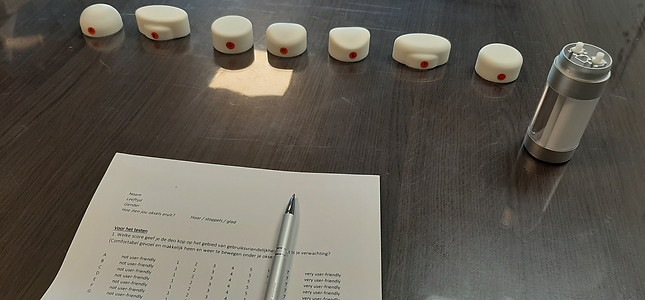

Usability tests to aim for a more user-friendly shape of a deodorant top.

CAREGIVER BELT

Designing and engineering a belt that will help the caregiver work easier and more efficient.

-

Building a prototype to test the functionality and the assembly of this application.

-

Including 3D printing, cutting and sewing fabric, assembling and connection of the wiring system.

-

Organising and performing test procedures that give insights into functionality and assembly.

-

Presenting and discussing the 3D model updates within the project team.

-

Identifying and analysing potential issues and setting FMEA (Failure Mode and Effect Analyse).

Build and test a prototype of a new product idea to help caregivers to work more easily.

In the last three years I have taken several internal courses:

-

Circular Product Development Course - 1 day

-

Idea Generation Management Course - 1 day

-

Personal Leadership – 1 day

-

Plastics Course - 3 day

-

Siemens NX CAD modeling - 5 days

COURSES

Back

Overview of some concepts with weight savings